UTILITY

MAINTENANCE

& INSPECTION

Sewer Line Air Test

An sewer line air test for sanitary purposes is a method for detecting leaks in a sewer system using artificial intelligence to analyze data. This approach typically involves a low-pressure air test combined with a specialized inspection tool to provide a more accurate and efficient assessment of the pipe’s condition.

Benefits of a Sewer Line Air Test

- Removes Tough Buildup: Effectively clears grease, roots, scale, and debris from inside pipes.

- Prevents Clogs and Backups: Clears blockages before they cause serious problems.

- Improves Flow Efficiency: Restores pipe capacity and keeps systems operating smoothly.

- Reduces Maintenance Costs: Extends the life of underground infrastructure by preventing damage.

- Environmentally Safe: Uses water-based, non-chemical cleaning methods.

- Ideal for Preventative Maintenance: Keeps systems in top condition and avoids emergency repairs.

How a sewer line air test works

- Low-pressure air test: Technicians use inflatable plugs to seal a section of the sewer line between manholes. Low-pressure air (typically 3.5–4.0 psi) is pumped into the sealed section.

- Pressure stabilization: The air is allowed to stabilize, which accounts for changes in air temperature. The test period begins once the pressure is stable.

- Monitor pressure drop: Technicians monitor the air pressure drop over a specified period. If the pressure drop exceeds a certain threshold (e.g., more than 1.0 psi), it indicates a leak.

- Inspection analysis: This is where AI differs from a standard air test. Instead of relying solely on the pressure drop, a tool like Burgess & Niple’s “PipeAId” uses machine learning and computer vision to analyze inspection data from the sewer line. This data can come from sources like CCTV (closed-circuit television) footage.

- Data processing: The tool processes the inspection data to detect and classify defects, pinpointing the specific location of leaks, cracks, and other issues within a few feet.

- Detailed report: It generates a comprehensive report that provides an objective and unbiased condition assessment of the pipeline. It can even compare current data with historical data to determine the rate of deterioration

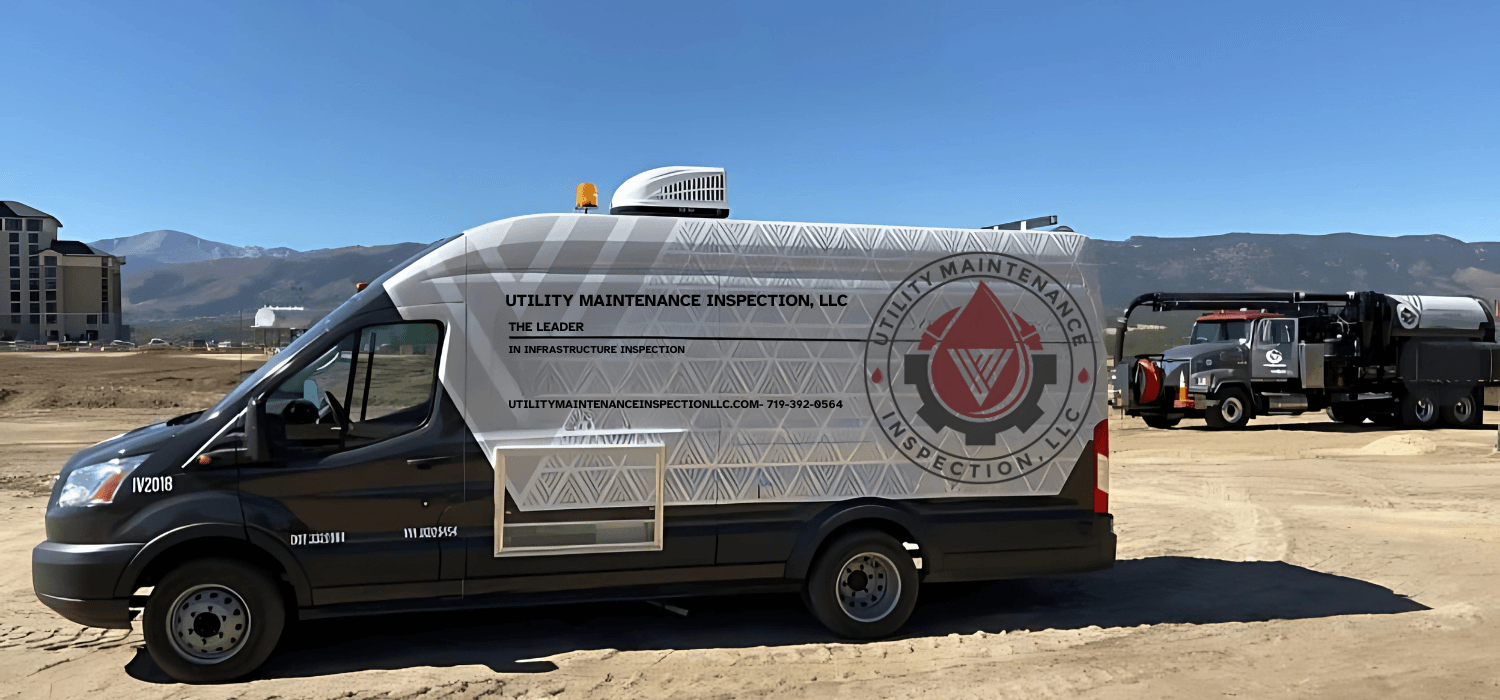

Utility Maintenance Inspection, LLC

@2025 All Rights Reserved. Website Built By Pink Hercules Media. Designed with WordPress