UTILITY

MAINTENANCE

& INSPECTION

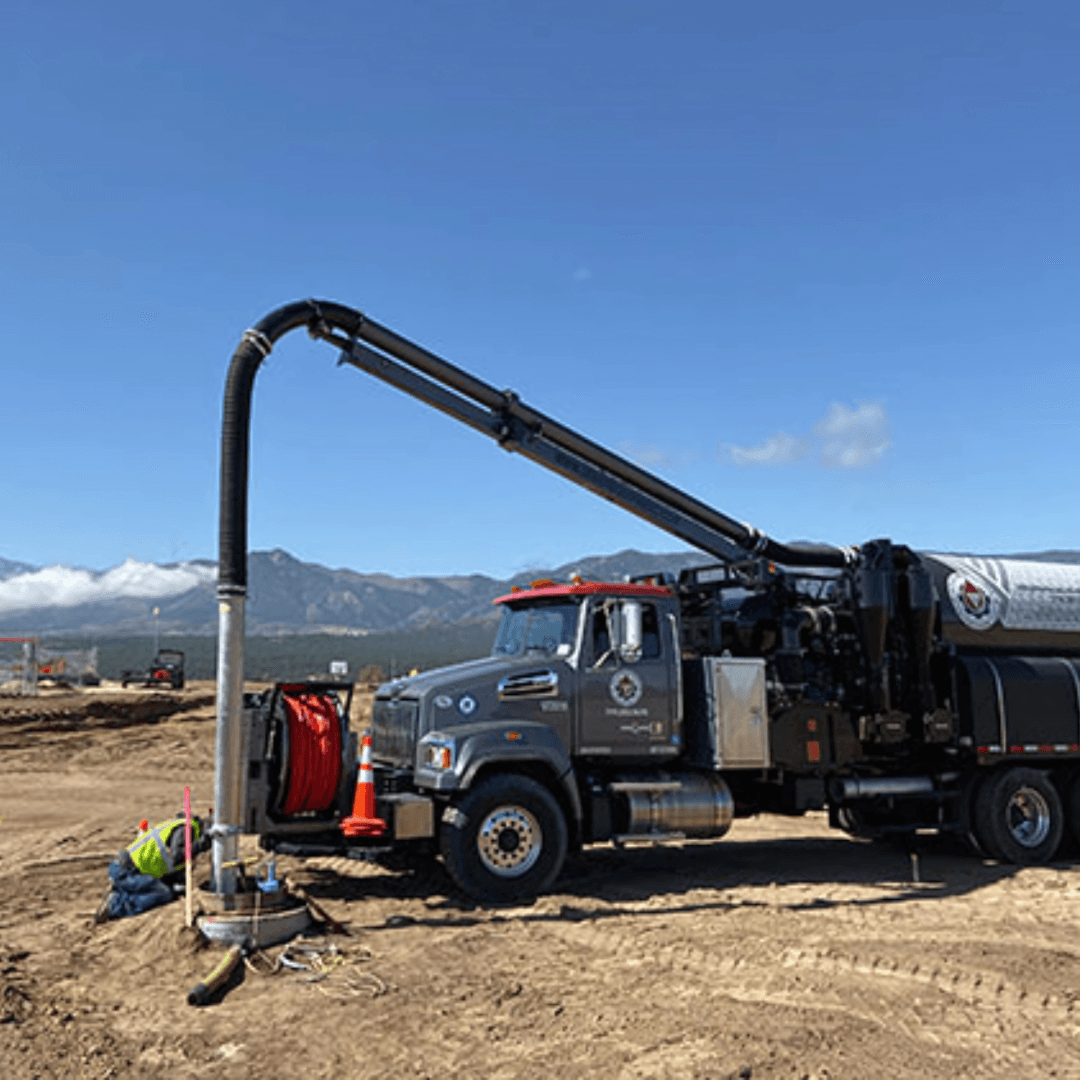

Hydro Excavation

Hydro excavation is a non-destructive digging method that uses high-pressure water and a powerful vacuum system to break up and remove soil. It’s commonly used to safely expose underground utilities, pipes, and cables without damaging them.

How It Works:

- High-pressure water is sprayed onto the ground to loosen the soil.

- The resulting slurry (mud and water) is then vacuumed up into a debris tank.

- This exposes underground infrastructure cleanly and precisely.

Key Benefits:

- Safe: Minimizes the risk of damaging buried utilities like gas lines, water pipes, or fiber optics.

- Accurate: Allows for precise digging in tight or sensitive areas.

- Efficient: Reduces backfill, repair, and restoration costs.

Hydro excavation is widely used in utility maintenance, construction, and municipal work for tasks like pole installation, daylighting (exposing utilities), slot trenching, and more.

Jet Rod & Vac Trucks

Jet Rod and Vac Truck

A Jet Rod and Vac Truck combines high-pressure water jetting with powerful vacuum suction to clean and maintain sewer and storm drain systems. The jet rod blasts away debris, grease, and blockages inside pipelines, while the vacuum system removes the waste material for proper disposal. This method is highly effective for clearing clogs, cleaning catch basins, and performing regular maintenance on underground infrastructure.

Here are the key benefits of using a Jet Rod and Vac Truck:

Benefits of Jet Rod and Vac Truck Services

- Efficient Cleaning: Quickly clears blockages, grease, sludge, and debris from sewer and stormwater systems.

- Prevents Backups: Regular maintenance helps prevent costly sewer overflows and flooding.

- Non-Destructive: Cleans pipes without damaging infrastructure.

- Environmentally Friendly: Removes waste safely and allows for proper disposal.

- Versatile: Effective for cleaning pipes, catch basins, manholes, and culverts.

- Reduces Downtime: Minimizes disruption to public or private property during maintenance.

- Improves Flow Capacity: Keeps drainage systems operating at full efficiency.

HDTV Inspections Of Underground Utilities

HDTV Inspections of New and Existing Underground Utilities

Our high-definition video inspections provide a clear, detailed view of underground utility lines, both new and existing. Using advanced CCTV camera technology, we can accurately identify blockages, cracks, misalignments, and other issues within sewer and stormwater systems. This non-invasive method allows for precise condition assessment, documentation, and maintenance planning, helping you avoid costly repairs and ensure long-term infrastructure performance.

Benefits of HDTV Inspections

- High-Resolution Clarity: Captures detailed visuals of pipe conditions, making it easier to detect cracks, blockages, and structural issues.

- Non-Invasive: No digging required as inspections are done from access points like manholes or cleanouts.

- Accurate Diagnoses: Pinpoints exact locations and nature of problems, reducing guesswork and unnecessary excavation.

- Prevents Future Failures: Helps identify early signs of wear or damage, allowing for preventative maintenance.

- Ideal for New Installations: Confirms proper installation and alignment of newly constructed utility lines.

- Cost-Effective: Minimizes the need for exploratory digging and unexpected repair costs.

- Comprehensive Reporting: Provides video footage and documentation for compliance, permitting, or asset management.

Underground Utility Detection

Pipe locating with a Sonde involves inserting a small, battery-powered transmitter (the sonde) into a pipe and then using a handheld electromagnetic locator (receiver) to detect its signal and map the pipe’s path on the surface.

Underground Pipe Cleaning

Our underground pipe cleaning services are designed to remove debris, grease, roots, and sediment buildup from sewer and stormwater systems. Using high-pressure water jetting (hydro jetting) and advanced equipment, we ensure pipes are cleaned thoroughly and restored to full flow capacity. Regular cleaning not only improves system performance but also helps prevent blockages, backups, and costly repairs.

Benefits of Underground Pipe Cleaning

- Removes Tough Buildup: Effectively clears grease, roots, scale, and debris from inside pipes.

- Prevents Clogs and Backups: Clears blockages before they cause serious problems.

- Improves Flow Efficiency: Restores pipe capacity and keeps systems operating smoothly.

- Reduces Maintenance Costs: Extends the life of underground infrastructure by preventing damage.

- Environmentally Safe: Uses water-based, non-chemical cleaning methods.

- Ideal for Preventative Maintenance: Keeps systems in top condition and avoids emergency repairs.

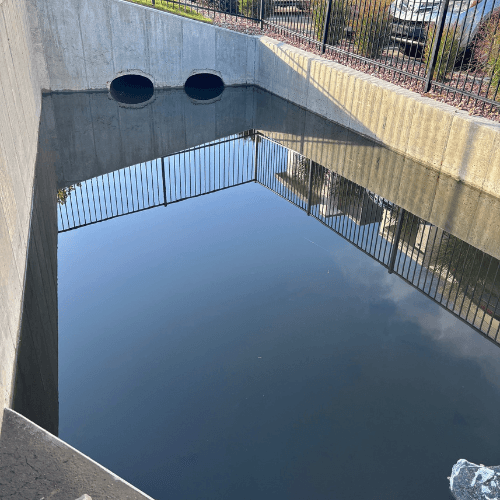

Detention Pond Cleaning & Maintenance

Proper cleaning and maintenance of detention ponds are essential for effective stormwater management. Over time, sediment buildup, debris, and overgrown vegetation can block drainage and reduce the pond’s capacity to control runoff. Our team provides thorough cleaning services including sediment removal, debris clearing, and vegetation control to restore full functionality and ensure compliance with local regulations.

We also perform regular inspections to identify issues early and maintain system performance year-round.

Benefits of Detention Pond Cleaning & Maintenance

- Protects Property and Infrastructure

- Prevents Drainage Issues and Flooding

- Maintains Stormwater Capacity and Flow

- Removes Harmful Sediment and Debris

- Controls Unwanted Vegetation and Erosion

- Supports Environmental and Regulatory Compliance

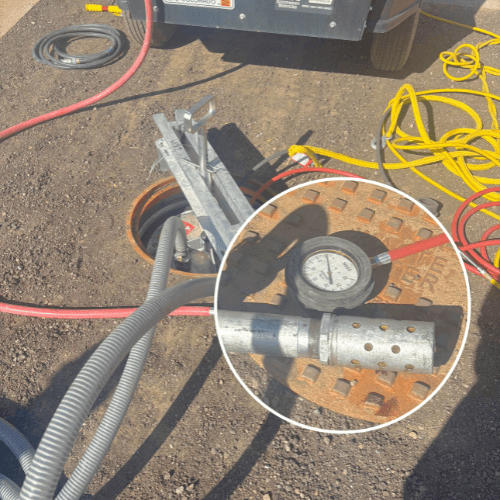

Manhole Vacuum Tests

A manhole vacuum test is a process that uses a vacuum to identify leaks in a manhole structure by measuring the time it takes for a 10-inch mercury (Hg) vacuum to drop to 9 inches of mercury (Hg). The test involves sealing the manhole’s inlet and outlet pipes with temporary plugs and using a test head (either a flat plate or inflatable bladder) to seal the top. A vacuum pump then creates a negative pressure, and if the vacuum holds for the required time, the manhole passes; otherwise, repairs are needed.

Benefits of doing a Manhole Vacuum Test

The purpose of a manhole vacuum test is to verify the structural integrity and watertightness of a manhole before it goes into service or during maintenance checks

- Ensure there are no leaks – preventing groundwater from seeping in (infiltration) or sewage from leaking out (exfiltration).

- Protect the environment – stopping contamination of soil and groundwater.

- Reduce treatment costs – keeping excess water from entering sewer systems and overloading treatment plants.

- Confirm quality of construction/repairs – making sure joints, seals, and materials were installed correctly.

- Meet regulatory standards – most municipalities and utility companies require proof of watertightness before acceptance.

Sewer Line Air Test

An sewer line air test for sanitary purposes is a method for detecting leaks in a sewer system using artificial intelligence to analyze data. This approach typically involves a low-pressure air test combined with a specialized inspection tool to provide a more accurate and efficient assessment of the pipe’s condition.

Benefits of a Sewer Line Air Test

- Removes Tough Buildup: Effectively clears grease, roots, scale, and debris from inside pipes.

- Prevents Clogs and Backups: Clears blockages before they cause serious problems.

- Improves Flow Efficiency: Restores pipe capacity and keeps systems operating smoothly.

- Reduces Maintenance Costs: Extends the life of underground infrastructure by preventing damage.

- Environmentally Safe: Uses water-based, non-chemical cleaning methods.

- Ideal for Preventative Maintenance: Keeps systems in top condition and avoids emergency repairs.

How a sewer line air test works

- Low-pressure air test: Technicians use inflatable plugs to seal a section of the sewer line between manholes. Low-pressure air (typically 3.5–4.0 psi) is pumped into the sealed section.

- Pressure stabilization: The air is allowed to stabilize, which accounts for changes in air temperature. The test period begins once the pressure is stable.

- Monitor pressure drop: Technicians monitor the air pressure drop over a specified period. If the pressure drop exceeds a certain threshold (e.g., more than 1.0 psi), it indicates a leak.

- Inspection analysis: This is where AI differs from a standard air test. Instead of relying solely on the pressure drop, a tool like Burgess & Niple’s “PipeAId” uses machine learning and computer vision to analyze inspection data from the sewer line. This data can come from sources like CCTV (closed-circuit television) footage.

- Data processing: The tool processes the inspection data to detect and classify defects, pinpointing the specific location of leaks, cracks, and other issues within a few feet.

- Detailed report: It generates a comprehensive report that provides an objective and unbiased condition assessment of the pipeline. It can even compare current data with historical data to determine the rate of deterioration

Utility Maintenance Inspection, LLC

@2025 All Rights Reserved. Website Built By Pink Hercules Media. Designed with WordPress